In the era of connected things, product design and engineering are more challenging than ever before. Physical design and performance characteristics must first be determined, and the operating environment understood. But expectations change when products become connected things, because the requirements imposed by the operating environment may become far more complex and dynamic.

Consider, for example, the humble scooter. Until now, a basic scooter needed two wheels, a platform, a steering mechanism, and a braking mechanism. But to support an “on-demand personal electric vehicle sharing network,” the scooter also needs a battery, location tracking technology, and drive mechanism. If it is to be used in bike lanes on streets, it should meet certain safety and performance requirements. It needs to interact with mobile devices and, in some manner, communicate its location and status. It must be unlocked for authorized users and locked otherwise. It must be charged and sometimes repaired, and the network management system must be involved in all of this.

To support these requirements, the product engineering will need to extend to include electronics, embedded software, and communications capabilities. But beyond the basic technical product engineering requirements, the product engineering must also consider the expected business operating models and user requirements.

A mobile app for users must be created and the entire user’s experience carefully designed. How does someone find a scooter? Can they reserve it in advance? How do they unlock it? How do they end a ride and release the scooter? If consumer payment is involved, how can it be handled securely? What data do the scooter and app need to generate? How do they interact? Who needs to have access to the various bits of data generated? When, how, and for how long? Who should not have access? Does the scooter manufacturer need access to any data? Are there data privacy issues that need to be managed?

To support the envisioned business model, is there a need for a digital twin that mimics the scooter’s behavior? How is it supported and maintained? Are accelerometers, location, or other sensors needed? How can users tell if a scooter is charged? If third parties will recharge the scooters, how will they interact with it and with the network? How will they be paid securely? Who will own the scooter? Who will maintain it? How will they be kept informed? Does the scooter need special branding or physical or electronic tagging for owners or maintainers?

A back-end software system is also needed. How should it be implemented? Is a support staff required? In some cases, there may be a requirement for customized scooters. What degree of customization should be supported? How should customers interact with product engineering? With sales? Who prioritizes the work? All these questions – and more – may need to be considered and perhaps resolved during the design and engineering of the scooter. Some of the answers may come from product engineers, but many will be determined by sales and marketing, customer care, service, or other organizations.

So, let’s step back for a moment and consider the design requirements for the connected products of the 21st century.

The in-service or operating ecosystem for a product determines its requirements. In the case of the scooter and other consumer goods, the expected operating environment are public streets and communities. Other products will operate out in the field in industrial, agricultural, mining, or similar settings. Still others will operate as assets in factories or production plants. In ecosystems such as these, the explosion of connected things, combined with advanced analytics to exploit the generated data and mobile devices to communicate to frontline users, are driving a lot more complexity. Established business models are being disrupted as new ways of owning, using, and maintaining assets are introduced. This shifts derived value from assets as physical objects to the services and outcomes they can support.

Connected industrial products, such as pumps, blenders, compressors, robots, packaging machines, and the like, will spend the majority of their asset lifecycle operating in production plants or factories. Traditionally, using and supporting these assets has been the province of plant operations and plant maintenance and engineering personnel, who use available software tools and other methodologies to maximize the asset’s contribution to the production goals of the plant. These often include asset management or maintenance applications, as well as execution applications including planning, tracking, quality, reporting, and the like.

The availability of connected machines is potentially disruptive to established production and maintenance scenarios like this. Connected environments surface machine data that was heretofore unavailable, enabling new business models. New systems may monitor the assets, and new actors may interact with the assets in new ways. The figure, “The 21st Century Industrial Production Operations Ecosystem,” depicts this for industrial plant operations. Similar diagrams may be constructed for assets operating in the field - such as mining or agriculture. In other cases, such as automotive, where the assets operate in public spaces and both the assets and ecosystems are evolving quickly, additional factors might need to be considered.

It is important to focus on the “operate” phase, because this is where the asset’s value is delivered. But this phase is also where many emerging, disruptive technologies can have a transformative impact on operations and business performance. It is no longer enough to merely address the asset’s availability, reliability, and risk. It may also be appropriate to consider potential new business processes enabled by smart, connected assets.

It is useful to frame any analysis of production operations requirements for a product (asset) with a broad, comprehensive view of the 21st century ecosystem as shown in the figure. Unlike the hierarchical (levels 0–4) Purdue model, which posits a bottoms-up perspective focused within a plant and with a limited notion of business systems interactions (primarily planning and logistics); the 21st century perspective should explicitly consider multiple plants and the possibility of more robust interactions with business systems, engineering systems, supply chain systems, expanded services, and customers. Unlike supply chain models (Design –) Source – Make – Deliver, or asset lifecycle models Design/Build – Operate/Maintain – Retire/Dispose, the primary focus here is on real-time, day-to-day production operations, where disruptive technologies are poised to make a significant impact on not only efficiency, but also responsiveness and operating performance. It’s not that any of these models were wrong or are somehow no longer valid. To be sure, they have provided the framework to get us to where we are today. But they do not adequately capture the requirements going forward.

Production operations in the 21st century incorporate new ways of doing things. Things are accomplished with a combination of internal and external actors (such as asset manufacturers, third-party machine monitoring services, spare parts suppliers, etc.), putting new demands on data requirements and cybersecurity strategies. New types of data are being generated (from wearables, vision systems, machine health sensors, etc.) and newly available digital twins and machine learning systems can work at various levels to optimize the overall system in synchrony with the needs of customers and business operations.

Customers in the industrial equipment sector, comfortable with easy access to advancing technologies at home, have begun to expect a lot more from their machine providers. At the same time, industrial equipment companies are adopting new business models built on much closer customer relationships because they know it provides a means of unique differentiation that will be key to their continued success. This dynamic derives from the introduction of disruptive technologies that enable products to be connected, smart, and more responsive to customer needs.

Optimizing the experience of your customers as they interact with your company, its supportive ecosystem, and your products and services is critically important. The modern customer experience is based increasingly on shared responsibilities for designing, operating, and maintaining products, shared data, and innovative and evolving business practices. Creating a robust, ongoing relationship is the goal. In practice, building this relationship often means executing a series of quick turnaround collaborations in which the supplier works closely with its customer to introduce a new product to meet a developing market opportunity.

Where possible, cultivating a supplier-customer relationship that is marked by cooperation and mutual gains, rather than a series of transactions, has many benefits. Achieving this with the bulk of your customers, however, is no small undertaking, and is likely to involve changes impacting people, processes, and systems within your company and externally.

The new industrial customer experience (ICX) should be a pillar of any industrial company’s digital transformation program. It requires cultivating a dynamic, innovative, and mutually beneficial coalition with each customer. In return, it provides a business outcome-driven differentiator to guide internal programs, projects, and allocations. It is not sufficient to initiate digital transformation programs based solely on the contemporary emergence of potentially disruptive technologies or traditional operating metric, such as cost cutting. Nor is it enough to focus on changes to business processes and norms driven by that technology – without programs designed to enhance the customer experience. Industrial equipment companies must embrace digitalization to nurture, extend, and differentiate their relationships with customers.

The expectation of connectedness profoundly changes the dynamics of product transactions between manufacturers and customers. We see a trend toward ongoing relationships and more services, instead of a series of one-and-done sales transactions. As they now experience in their personal lives, today’s industrial customers expect a digital, customized, and highly servitized experience when dealing with their equipment suppliers. In some cases, this manifests itself as a subscription to the product or its output. More commonly, or at least initially, it may mean the supplier provides, or at minimum provides the means for, live monitoring, diagnostics, and predictive alerts about machine performance and possible failures.

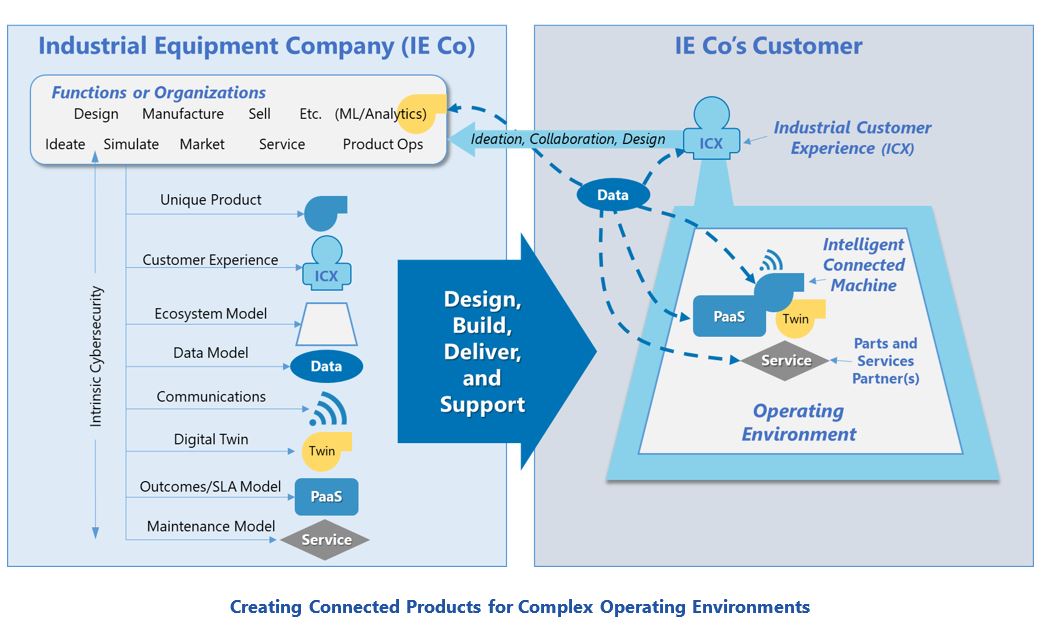

With connectedness, it's not enough to deliver the product itself; industrial equipment companies must support their customers by designing the complex sophisticated machines while modeling or designing the associated ecosystem, data, maintenance, digital twin, and industrial customer experience requirements. In doing so, they must involve all the necessary disciplines, departments, and stakeholders – including customers – during each phase of the product and service lifecycle.

To accomplish this, high-performing industrial equipment companies collaborate broadly and, together with their customers and partners, act as one intelligent, connected system. Like any modern company, industrial equipment companies want to grow their business, improve profitability, and strengthen bonds with their customers by improving the customer experience. This requires the use of a modern engineering and data management system that supports virtual, model-driven design and multi-discipline collaboration based on common data.

When considering your customer’s experience, remember that their business is also all about serving their customer and enhancing that customer’s experience. Your product may be part of the value chain that produces and delivers products and services to their customer. For example, a packaging machine maker’s customer uses the machine to make the packages that carry the product and marketing to the end consumer. So, the packaging machine maker must offer the right product and set of services to enhance not just its own customer’s experience, but the experience of its customer’s customer as well. To facilitate this, the packaging machine maker benefits from using a modern digital platform with capabilities, such as virtual reality, 3D visualization, social analytics, knowledge sharing, IP management, and virtual simulation.

Industrial equipment companies need to work closely with their customers throughout the product lifecycle. They need to engage them early on and provide tools for the customer to participate in designing their interactions with the product in its modeled environment. They also need to support their customers with real-time monitoring and diagnostic services during the operating phase.

Instead of engaging the customer in a journey with touchpoints along the way, the emerging model welcomes the customer into a supportive coalition that provides for nearly every need - from conceptualizing innovative product ideas, interactions, and ecosystems, to realizing them and the environments they were designed for, to the adaptations and services needed throughout the whole lifecycle.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us