At the NAMUR General Assembly held on November 8 and 9, 2018, two topics were directly related to Information Modelling or data modelling. Data models enable information interoperability by specifying which information is stored where, and what the content of that information is. Models for asset information enable the efficient management of information of an asset. Asset information is seen as increasingly important and forms a basis for engineering, qualification and compliance, commissioning, operation, safety, maintenance and decommissioning. Asset information should be accurate and up-to-date make operational or maintenance-related decisions, and provide historical snapshots of the asset state, to be able to research operational and maintenance history as well as searching for root causes of incidents.

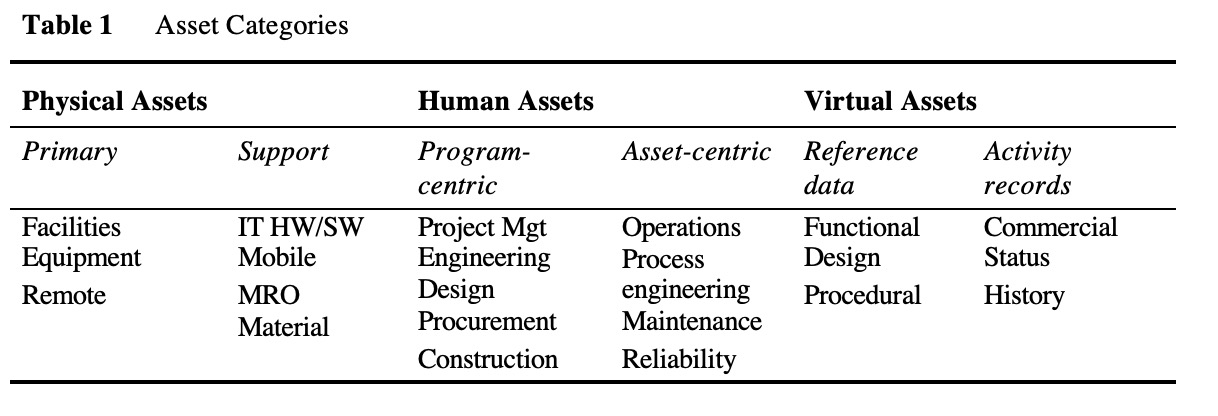

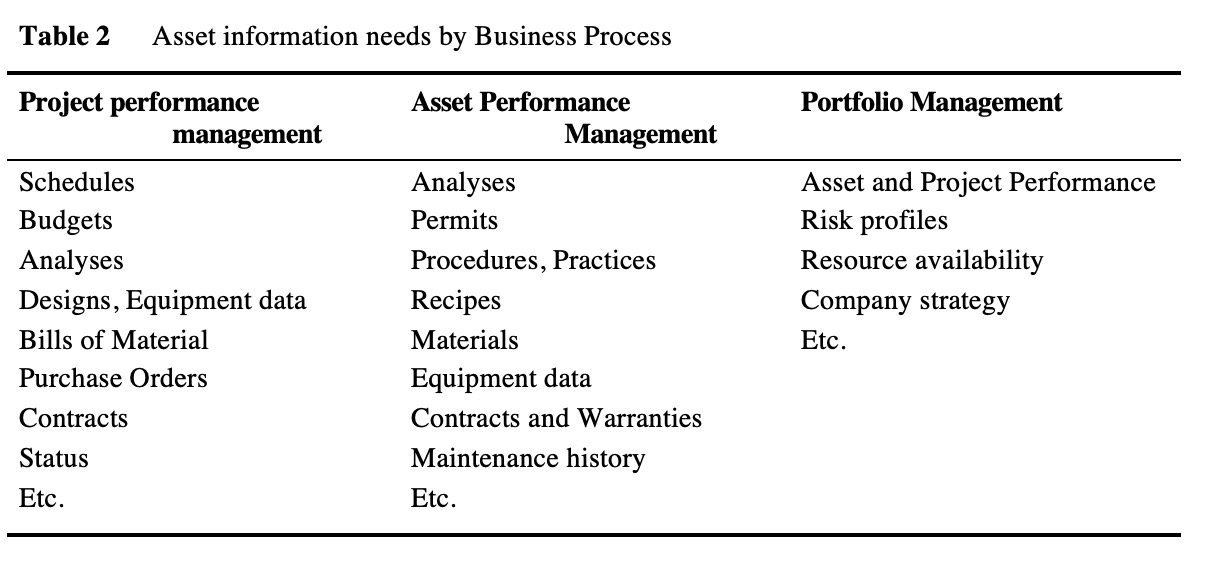

Assets should be seen in the broadest possible way, according to ARC (see Table 1), and should contain all information required for at least the three main business processes: project performance management, asset performance management, and asset portfolio management for example the information indicated in Table 2. The process of collecting, managing, updating and making this information available, is called Asset Lifecycle Information Management in ARC’s terminology. For more information, see “Asset Information Management: From Strategy to Benefit” by Valentijn de Leeuw and Sid Snitkin, and ARC’s Strategy Report “Standards-Based Asset, Information, and Performance Management”.

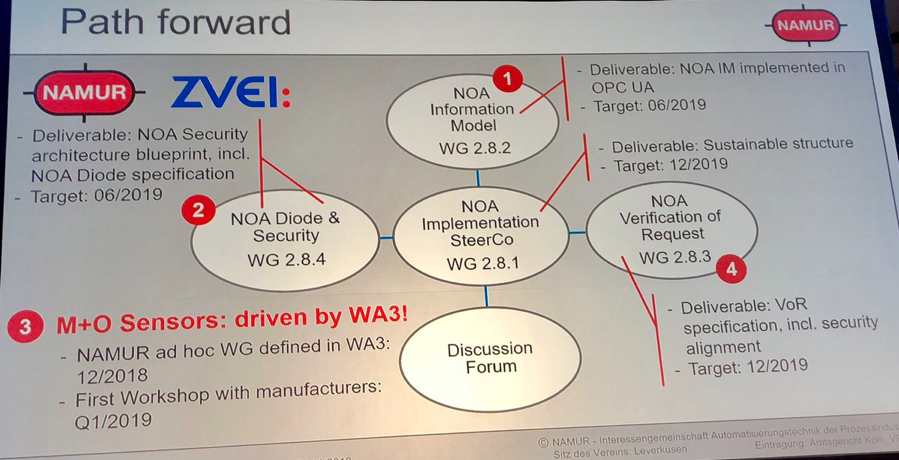

Jan De Caigny from BASF provided an overview of the progress on the Namur Open Architecture (NOA), essentially a standardized information model (1) to securely (2) transfer field data from within the control system to cloud or on-premise applications for monitoring and optimization (M+O) purposes. Suggestions from M+O applications will be screened for authenticity (4) when proposed to the control system.

The main purpose is to reduce the cost of information, by strongly reducing the cost and effort of integration, while safeguarding real-time, deterministic process control and instrumentation. NOA demonstrators have shown that the principles behind NOA are sound and proof-of-concept installations show they can be transformed to technical specifications and standards that can lead to marketable products (3). NAMUR plans to test the security of the standard by hackers.

The path forward is to formulate the users’ requirements in a NAMUR recommendation (planned for the end of 2018), in parallel continue discussion with the German association of vendors (ZVEI) how it could become a technical specification and formulate a technical standard attached to the NAMUR recommendation. After that, an organization needs to be identified to determine compliance and certification.

The Namur Open Architecture can be used within the Module Type Package upcoming standard, the Open Group’s Open Process Automation initiative as well as the new Asset Lifecycle (ALC) data information model (see below)

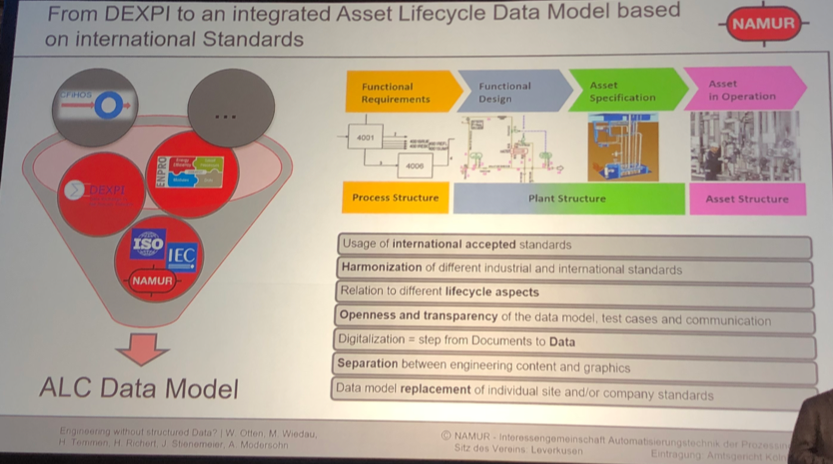

Michael Wiedau of Evonik reported on the project ALC Data Management. The goal is a future-oriented, optimized and harmonized way to deal with the needed data to develop, plan, operate and maintain our plants (assets) efficient, reliable and safe within the Asset Management principles – based on international standards.

NAMUR took the DEXPI apparatus and machine taxonomy and instrumentation models. The latter is based upon IEC 62424 and IEC 61987 (NAMUR recommendation NE100). These standards help transferring information from process design to electrical and instrumentation engineering and into design tools for electrical and automation (A&E) hardware engineering. In a next step, the NE 150 will be implemented to create the link between A&E hardware and A&E software engineering, or engineering design tools. Siemens will implement and market the data model.

The model will also be aligned with the CFIHOS (Capital Facilities Information Handover Specification), closely aligned with the ISO 15926 standard. The resulting standard will be proposed to DEXPI to augment its current model and will be aligned with NAMUR’s MTP.

Wilhelm Otten, also of Evonik, member of the NAMUR board and former president, reported on the implementation of the model in Evonik. As the slide below suggests, the model can be used for a wide variety of operational and asset performance management applications and relies for its information on a wide range of sources.

ARC strongly supports a widely used and standardized asset information model and believes it is key to provide context for asset and operational data, that improves decision making, data integrity and quality governance, and can form the basis for advanced applications such as 3D modeling, simulation and optimization, aspects of the much wanted “digital twin”. The approach to combine different existing standards and align with similar standards is the best possible to create broad adoption.