The edge of industrial internet-enabled architectures is becoming increasingly important. This is largely due to its often critical role in determining the success of digital transformation strategies. Initially focused on delivering timely, clean data to cloud-based applications, the edge has emerged as an entirely new ecosystem within the overall enterprise architecture.

Solution architects now rely on the edge not only for cloud integration, but also as a solution to the cloud’s shortcomings in areas such as latency, security, cost containment, and isolation for production environments. Edge computing applications, particularly high-value analytics and artificial intelligence (AI) delivered via machine learning (ML), al-low data to be processed near its source.

Recognition of the rising importance of the edge is reflected in the spike of investments targeted at this space. IT and OT suppliers alike are introducing new Industrial IoT edge hardware, software, and solution offerings. This latest crop of new and updated industrial IoT edge solutions, what we call “Industrial IoT Edge 2.0,” represents important improvements in ease-of-use, self-service, and turnkey operation, while emphasizing business outcomes and application-specific solutions versus pervasive infrastructure.

Ongoing evolution of the emerging, diverse IIoT edge ecosystem continues to expand the connect, compute, and store capabilities of edge devices and systems. New entrants, such as edge servers, fog nodes, and edge software platforms, have emerged to meet these requirements, with software-based functionality now the primary vehicle for added value and product differentiation.

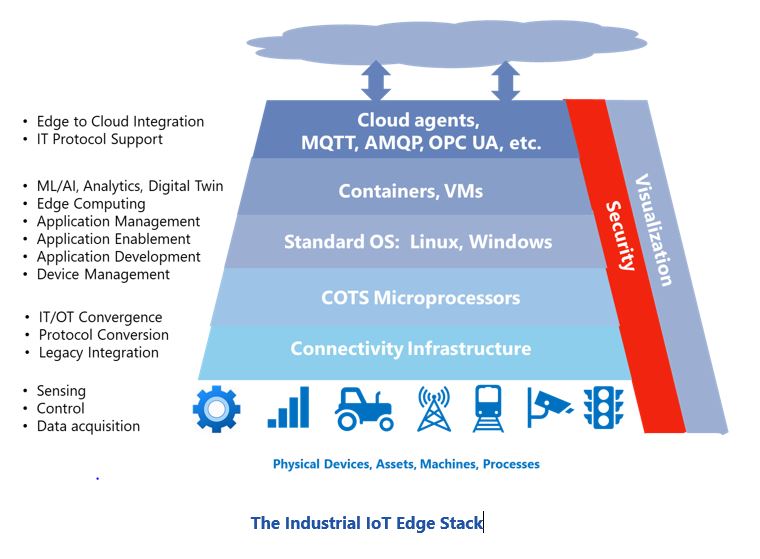

ARC Advisory Group defines the Industrial IoT edge as the place where physical devices, assets, machines, processes, and applications intersect with internet-enabled portions of the architecture. Industrial IoT edge devices provide input to, and may receive output from, industrial inter-net-enabled systems, applications, and services, but reside outside of clouds and data centers. Edge systems typically operate on-premises but are distinct from traditional non-internet connected automation and control systems.

The emerging industrial IoT edge ecosystem is much richer and more nuanced than any MES or network infrastructure layer or site of IT/OT convergence. This tier of the architecture represents a functional spectrum ranging from connecting devices and converting automation protocols, to developing, deploying, managing, visualizing, and executing applications critical to achieving business improvement and competitive advantage. Inherent in this is the convergence of not only IT and OT, but also compute and connect.

Suppliers are responding to the emergence of the Industrial IoT edge by expanding the range of hardware, software, and solutions targeted to serve its broadening functional spectrum. Traditional automation gateways used for simple protocol conversion have morphed into edge computing devices that support standard microprocessors and COTS operating systems, particularly Linux, as well as containers. At the same time, a new “thick edge” tier populated with high-end edge servers designed to serve escalating edge compute and storage requirements is being forged above the network infrastructure layer.

The software landscape is similarly evolving. Industrial IoT edge platforms have emerged from their origins in device connectivity, visualization, security, and management to full-blown IT/OT integration and application execution environments capable of serving escalating requirements at this tier of the architecture. These platforms are increasingly viewed as the vehicles for local computation and application execution in service to Industrial IoT-enabled business improvement processes.

One of the most consistent responses we receive regarding criteria for success in Industrial IoT projects is the need to focus on a clearly-defined business outcome. Projects intended to simply test technical concepts are consistently the most likely to die on the vine. In the current market this translates into emphasizing specific use cases rather than the pervasive IoT infrastructure anticipated in early visions. This emphasis on outcomes is one of the most prominent characteristics of Industrial IoT Edge 2.0.

Savvy end users recognize that the Industrial IoT should be pursued not just for technology’s sake, but to achieve concrete business out-comes. Defining your desired outcome is a place to start determining the best solution since offerings vary. Early Industrial IoT edge implementations tend to emphasize outcomes such as reduced machine downtime (connected products), incremental performance and safety improvements (connected operations), cost savings for service operations (connected service), and both product and service innovation. Industrial IoT edge solutions enable these outcomes through applications such as analytics and ML-based predictive maintenance capabilities, although the spectrum of targeted activity continues to broaden.

Industrial IoT Edge 2.0 offerings place greater emphasis on turnkey solutions that address specific outcome-oriented use cases. While early industrial IoT edge solutions, such as preventive maintenance, tended to be more horizontal in application, the emphasis on outcome-focused use cases is driving an increasingly vertical orientation as solutions gain traction in segments such as industrial machinery, automotive, transportation, and other early-adopter industries. These activities indicate a shift away from a simple “run the operations” mentality to use of real-time data analytics to rethink competitive fundamentals.

Hardware and software suppliers alike are looking for combined solutions packages to differentiate themselves and add incremental value, particularly to increasingly commoditized network infrastructure hard-ware. Offerings such as ADLINK’s Digital Experiments as a Service (DXS), Advantech’s Solution Ready Packages (SRPs), Cisco’s Validated Designs, Dell’s IoT Connected Bundles, and the Siemens MindSphere application development centers and marketplace offerings are just some examples of the migration toward outcome-oriented solutions offerings.

Originally viewed as the boundary between IT and OT, the scope of the Industrial IoT edge continues to evolve. Escalating requirements for edge-to-cloud connectivity, as well as compute power and storage to serve edge computing requirements, is driving further evolution. Edge devices of all types, including edge servers, network infrastructure devices, and endpoints are delivering ongoing price/performance improvements - furthering the convergence of compute/connect and continued downward migration of edge processing.

At the lower end lies the need for basic device connectivity and automation protocol conversion, which has led to significant growth in industrial IoT network infrastructure markets such as gateways. This OT or “thin” edge is characterized by its primary role of converting automation-centric data to data that can be consumed in the IT environment. This is true particularly for converting polling protocols typical to legacy industrial environments to more IT-friendly pub-sub communications (like MQTT), that can serve data to any applications that choose to subscribe.

This conversion of legacy protocols continues to move further down in the architecture, driving additional IT/OT convergence. Dedicated automation polling communications that bring in signals from legacy devices are pushed downward in favor of more IT-friendly publish-subscribe communications that make data more easily available throughout the IoT architecture.

Desire to process inputs at the edge and provide preprocessed analytics outputs to cloud applications, rather than a direct data deluge, is driving edge compute and store requirements. Resource-constrained thin edge devices such as gateways may not be able to meet these escalating compute and storage requirements for robust local edge applications. This has led to introduction of more powerful and less expensive server-like IIoT edge appliances that emphasize these capabilities for on-premise operation.

Descent of IT and cloud applications to the edge has led to the rise of an IT or “thick” edge that resides above the protocol conversion activity. Hardware suppliers, such as Cisco, Dell, HPE, Stratus, and others, have responded to the emergence of this tier with edge server-like devices that contain the incremental compute and storage capacity necessary to host and execute robust Industrial IoT edge applications.

Industrial IoT edge suppliers depict this tiering in a variety of different ways: thick edge versus thin edge, cloud edge versus device edge, IT versus OT edge, etc., and several suppliers have already parsed their offerings to execute in the different environments. Some view the distinction as ARM processor-based devices on the thin/OT edge and Intel at the thick/IT tier. This broadening spectrum of edge hosting possibilities should be incorporated into your industrial IoT deployment vision.

Conversely, Industrial IoT edge software platform providers, including the enterprise cloud players, are reducing their compute footprint to enable extension of their solutions all the way into intelligent endpoint devices. These small-footprint offerings typically target ARM or Rasp-berry PI type platforms. Edge software offerings from non-enterprise edge solution providers, like Rockwell Automation and GE Digital, can similarly function on endpoint devices.

Analytics and ML applications at the edge have attracted the attention of the enterprise cloud software suppliers, such as AWS, Google, and Microsoft, virtually all that target industrial applications. These providers are leveraging the data-rich industrial IoT edge as a primary means of delivering analytics-driven business improvement. Tremendous value also exists in providing preprocessed analytics output to the cloud – if not executing closed-loop ML at the edge itself.

Enterprise cloud providers have the ear of customer CIO/IT organizations, as well as significant resources to bring to bear at the edge. They also bring deep experience with many core software development capabilities, such as DevOps methods, UX, and microservices that will be needed at the edge.

They position edge offerings to their IT customers based on a common development and management environment as well as availability of large developer and support ecosystems. Extending their reach to the edge allows them to further leverage their strengths in data architecture, integration, and security. These providers are similarly responding to the calls for improved ease of use for developing, deploying, and managing their edge solutions.

One of the most compelling developments in this area is the potential impact of microcontroller hardware offerings, including those developed by the cloud providers themselves as well as third parties, to sup-port this migration. All three major enterprise cloud providers have announced their intent to provide hardware to enable data-intensive edge applications, such as AI and video analytics, as well as delivery of preprocessed output to the cloud. These suppliers are creating new apps and analytics models that are trained, developed, and managed in the cloud; but deployed at the edge.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us