What does your CEO care about most? In most cases, this is revenue and return on assets (ROA). What is not a priority? It’s not the number of maintenance technicians on staff. Unfortunately, most project justifications for predictive maintenance (the leading application for digital twins in operations and maintenance) focus on reducing maintenance costs, which often is not adequate to get executive attention and support.

Executives respond to their key performance indicators (KPIs) just like the rest of us. For nearly all C-level executives, their KPIs are in the profit and loss (P&L) statement and balance sheet. Predictive maintenance (PdM) prevents downtime which increases operating time, production volume, revenue, and profits. The justification for a PdM project should start with the increased revenue. Next, is conserving cash in the balance sheet by avoiding the need for replacement equipment and lowering work-in-process (WIP) inventory, which improves ROA. Improving revenue and ROA have a positive effect on executive KPIs and shareholder value – which gets executive attention and support. Key findings for project teams include:

When attempting to justify an investment in PdM financially, those involved typically focus on what they are familiar with i.e., maintenance activities. The identified business benefit involves reducing maintenance technician time and replacement parts. Usually, the financial analysis comes up short, with not enough return to justify the investment. A resourceful person will constrain the investment to get an acceptable return on investment (ROI).

A preventive maintenance strategy typically applies maintenance at double the expected frequency of asset failure[1]. In contrast, PdM applies labor just before the failure. Thus, preventive maintenance usually uses twice the labor and materials as PdM. The reduced maintenance cost is a commonly used justification for PdM. But maintenance can always find more useful jobs to do. After PdM project implementation, the maintenance technicians are assigned other tasks, with little or no reduction in headcount.

Production management will view the project as a success when they see a reduction in unplanned downtime and have more control of the production schedule. But, finance and the COO/CEO will view the project as a failure since headcount was not reduced to achieve the savings. Despite success from an operating viewpoint, the next project justification will be met with skepticism, which could be career limiting.

A financial justification based on reduced maintenance activities typically provides a weak savings (the numerator in an ROI calculation). To get an acceptable return, some project managers constrain the investment (the denominator). This approach limits the available resources which increases the risk of technical failure i.e., the PdM project doesn’t work or goes over budget – which becomes another career-limiting factor.

Moving beyond maintenance activities and into areas that improve the KPIs of C-suite executives may be outside the comfort zone of most maintenance professionals. However, this approach will improve project justification, increase available resources, obtain a higher level of success, and likely enable more career opportunities.

Like everyone else, executives respond to their KPIs. In their case, there’s a close link between the KPIs and compensation. Having a positive effect on these performance measures will get executive attention.

Executive metrics are well defined via accounting standards and publicly known via the company’s financial reports - particularly the P&L statement and balance sheet. Any fudging of the numbers will get the executive in legal trouble – so improvements must be real and verifiable by finance. Improving these reports will get positive executive support.

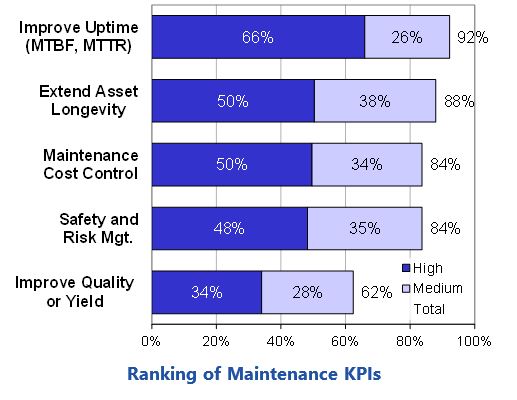

Based on ARC Advisory Group surveys, the leading KPIs for the maintenance function are uptime (including avoiding onerous unplanned downtime), asset longevity, cost control, and safety/quality.

Unplanned downtime interrupts production, which leads to missed schedules, lower capacity, and reduced revenue. Missed delivery dates reduce customer satisfaction, which has a longer lasting negative impact on revenue. The uptime metric directly affects revenue and profits in the P&L statement; key measures of executive performance.

Good maintenance practices, including predictive maintenance, enable assets to operate longer. These

Particularly in the discrete and batch process industries, WIP inventory allows downstream operations to continue if upstream equipment fails. With higher reliability and near-zero unplanned downtime, the WIP inventory can be reduced. Lower inventory reduces assets and increases cash, which improves the balance sheet.

In both cases, i.e., inventory and equipment, assets are lower, and cash is higher. This improves the “quick ratio” metric that financial analysts use to value the stock – helping drive higher stock price and shareholder value, which are also key measures of executive performance.

A key metric for overall performance of a business is ROA. This ratio contains the return (profits) in the numerator and total assets in the denominator. Using predictive maintenance to prevent unplanned downtime improves profits and reduces assets – both changes increase ROA. Again, this helps improve shareholder value.

Digital twins for asset management fall into two fundamental categories:

A nine-minute recorded webinar augments this Insight with graphics and further explanation at: https://www.youtube.com/watch?v=wMtzQ1Yei6g

This report focuses on financial justification of the performance digital twins, which are predominately applied for predictive maintenance.

The performance digital twins involve collecting real-time operational data, applying analytics to evaluate current conditions, and sending alerts when something deteriorates. Preventing unplanned downtime using PdM is a common application for performance digital twins. Unplanned downtime often cascades into major losses including revenue, WIP materials, and larger equipment repair costs.

PdM applications used to be expensive, difficult to support, and often abandoned when something changed that broke the software application. The introduction of cloud platforms with Internet of Things (IoT) and analytics lowered the application development costs and made it easier and more cost-effective to support the application over time. Rapid adoption of performance digital twins for PdM started in about 2015 due to the fast payback from preventing unplanned downtime and the associated revenue losses. Now, those PdM applications have started to expand in scope to include operational performance for quality, yield, energy conservation, and avoiding excessive stress from overrunning equipment.

The basis of a performance digital twin involves a mathematical algorithm that models a physical piece of equipment using real-time data. For PdM, a performance digital twin identifies deteriorating conditions. The scope extends beyond the model to include related business processes to fix the issue before the asset fails and results in unplanned downtime. Attributes of a performance digital twin include:

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us