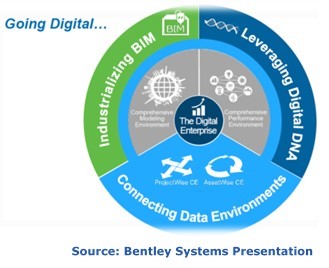

Anne-Marie Walters, Global Marketing Director, Bentley Systems’ presentation at the recent ARC India Forum highlighted the company’s portfolio of offerings and innovative solutions to drive industrial growth. The case studies and videos of reality modeling brought in a whole new dimension to asset performance and digital reliability monitoring. Her focus was on industrializing building information modeling (BIM) to speed project delivery and leveraging the digital DNA to improve asset performance, thus reducing both CapEx and OpEx to ultimately achieve optimal TOTEX, (Total Expenditures/Excellence).

Bentley included the Danfoss case study in its 2016 Infrastructure Yearbook, recognizing its innovation in asset performance. Danfoss, a supplier of refrigeration equipment, compressors, and controllers for supermarkets, required an integrated solution to help its customers view operational data at a more granular level. Bentley Systems’ AssetWise Operational Analytics solution provides Danfoss with real-time data for proactive operations and maintenance. Benefits include:

Alarm management and filtering of false alarms

Real-time temperature reporting to ensure refrigeration units operate within set parameters; saving energy without compromising food safety

Continuous monitoring helps anticipate and prevent breakdowns

Analytics optimize energy use through prescriptive load shedding, so energy can be put back into the grid for financial gain

Ms. Walter’s mentioned that in ARC’s recent market research reports on Engineering Design Tools for Plants and Infrastructure, and Asset Reliability Software & Services, Bentley Systems was positioned as the market leader in a number of key asset-intensive industries.

Ms. Walters began this section with videos on reality modeling and how Bentley’s solutions provide new options to capture, process, visualize and consume 3D data of existing assets.

Last year, Bentley updated its ContextCapture solution to process point clouds (in addition to photos) when generating a 3D reality mesh. A more recent update also enables users to input aerial and mobile LIDAR point cloud data to provide an innovative mapping solution.

As a result, to get an overall view of a plant and its processes, users can take photos of the equipment; get an aerial view and high-quality color visuals of the surroundings with drone photography, and create an “engineering ready” 3D reality mesh. Instead of operating the drone by ground personnel, now the drone’s flight path can be programmed by the engineer to better assess and inspect the site/plant. Quoting Bureau Veritas, a certification company that uses ContextCapture, “Reality modeling is becoming pivotal in many industries as it fundamentally changes the management of assets, reinventing the handling of inspections, maintenance, and training, while opening new doors to brand new services.”

In this context she spoke about Bentley’s coinage of the word “Inspectioneering.” This effectively combines multi-dimensional aspects of inspection and engineering – and is useful for asset reliability modeling. After the inspection is done, the engineer can see an asset on the screen, zoom in on the problem area, and more quickly find solutions to fix the problems. Further, she spoke about ProjectWise ContextShare cloud service, which enables sharing of large reality data sets among project stakeholders in larger organizations across the ecosystem, and with other Bentley applications such as its design tools.

An important aspect of Ms. Walters’ presentation was her discussion on Bentley Systems’ strategic alliance with Siemens. As she explained, the goal is to “drive new business value by accelerating digitalization to advance infrastructure project delivery and asset performance in complementary business areas.” The cooperation between the two companies extends across all business domains and covers systematic extension of the simulation portfolio; discrete manufacturing; process industry; energy management; mobility; and building technologies.

Some key takeaways from the Bentley presentation:

IT-OT-ET integration is vital to streamline business processes

Asset reliability modeling, digital engineering models, and operational analytics are key requirements of industry

Collaboration and cooperation are important to realize the digital enterprise