Basic process control, what we now call “level 2” in the Purdue Enterprise Reference Architecture, has been the basis for successful process manufacturing for decades. Industry has witnessed several revolutions in technology that have produced more accurate, precise, and faster process control leading to better product quality and throughput. Innovations have moved from mechanical, to electrical, and on to computational. Currently, the innovation in automation has moved further up the architecture, with mostly incremental changes at level 2.

The Open Process Automation Forum (OPAF), a forum of The Open Group, has stressed the need for standardization at level 2 to help reduce lifecycle costs. What, then, can industry expect in the future from this level in the automation architecture? How should end users prepare for basic control innovation?

Greeks and Arabs (in the period between about 300 BC and about 1,200 AD) had a preoccupation with keeping accurate track of time. In Egypt, about 270 BC, Ctesibius described a float regulator for a water clock, a device similar to the ball and cock assembly in a modern toilet. This has been identified as the earliest feedback-controlled mechanism. The appearance of the mechanical clock in the 14th century made the water clock and its feedback control system obsolete.

In their Book of Ingenious Devices (850 AD), the Persian Banū Mūsā brothers described several automatic controls. The brothers developed two-step level controls for fluids, a form of discontinuous variable structure controls. The book also described a feedback controller.

Many forms of mechanical devices have been used for control. Innovations occurred slowly and methodically. In the late 1940s, however, the transistor was invented, opening new opportunities for innovation via electrically-based automation. In the 1960s, innovative engineers began to leverage computer processing in automation. Suddenly, the controls could be easily changed, repurposed, and made to interact with other controls.

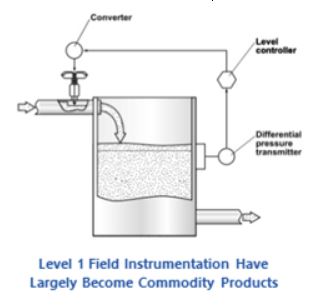

Later, in the 1970s, networking technology was introduced allowing greatly increased data exchange between controllers and operators. Compute power and memory increased, as well. In the 1980s and 1990s, this trend continued. Instrumentation suppliers also extended compute power and networking into field devices and the industry briefly flirted with control within and between field instruments.

In the last decade, industry witnessed a greater focus on securing level 2 control assets and reducing the labor needed to install, commission, and maintain those assets. However, when it comes to the basic process control technology, not much has changed.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Automation, Innovation, Level 2, Trends, Future, Open Process Automation, ARC Advisory Group.