When I listen to presentations about new products, technologies, strategies, and best practices my reactions occur in four distinct phases.

The first two phases are clear; so let’s move to phases 3 and 4 and find the roots of IT-OT integration, IIoT (Industrial Internet of Things), and Virtual Reality Simulation.

No man is an island unto himself. That a man cannot live in isolation was known centuries ago; he had to interact with others and live in a community. The same idea has been expanded across countries and industries. It was soon realized that organizations cannot operate in silos, they must collaborate both internally and externally. So, the next logical step was IT-OT integration; that’s why although it is new, it seems familiar.

Today, across industries people are talking about integrating the IT and OT (information and operational technologies) layers. Even at the recent Orlando forum there was a well-attended session that focused on the IT-OT convergence – the modus operandi, the challenges, and quantifiable benefits substantiated by successful case studies.

But now companies, such as Bentley Systems have added a third dimension - ET (engineering technologies). I first heard about IT-OT-ET integration at Bentley’s presentation at the India forum. I watched videos on reality modeling that increase joint opportunities in surveying and engineering. Some key takeaways from the Bentley presentation:

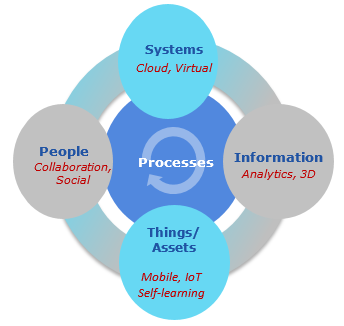

Sanskrit phrase – Vasudaiva kutumbakam – the world is one family. At the recent World Economic Forum at Davos, India’s Prime Minister Modi mentioned this phrase highlighting the importance of unity to solve global  problems. Moving ahead from the premise that the world is one family - we are all connected in different ways. In the industrial context it began to exemplify interconnectedness between people-systems-information–things; and that is what the IIoT is all about. The IIoT is all about connectivity, collaboration and convergence. New, but familiar.

problems. Moving ahead from the premise that the world is one family - we are all connected in different ways. In the industrial context it began to exemplify interconnectedness between people-systems-information–things; and that is what the IIoT is all about. The IIoT is all about connectivity, collaboration and convergence. New, but familiar.

Reams have been written about IIoT and how it is transforming the business landscape. The core of every conference is about the IIoT/Industrie 4.0 and implementation strategies to achieve operational excellence. The deeper interlocking of the digital world with the world of machines holds the potential to transform the global industry, and in turn many aspects of daily life, including the way many of us do our routine tasks. These innovations promise to bring/have already brought, greater speed and efficiency to industries as diverse as aviation, power generation, oil and gas, railways, and health care delivery. Clearly, the value proposition for the IoT opportunity extends beyond simple connectivity into the ability to build new products and services and achieve competitive differentiation.

Prevention is better than cure. This dictum was first applied in the field of medicine, but now it is relevant to software solutions – preventive and prescriptive analytics. To prevent a catastrophe/accident from happening it became necessary to simulate a real-life scenario to provide users with practical feedback when designing real world systems. This allows the designer to determine the correctness and efficiency of a design before the system is actually constructed. Simulation is the process of using computer-based modeling of a system to understand its behavior and predict the effect of changes. It represents a powerful method for analyzing, designing, and operating complex systems; providing a proven, cost-effective way to explore new processes and designs, without having to resort to expensive pilot programs or prototypes. The level of understanding that can be developed through simulation is seldom achievable by any other means.

According to ARC, process simulation and modeling has repeatedly demonstrated its engineering value as a tool for designing plants and processes. It also finds widespread engineering use in operations for process analysis, troubleshooting, de-bottlenecking, process improvement, developing control strategies, and training operators. More recently, however, it is becoming an everyday operational and model-based decision support tool that provides invaluable insight into process dynamics. Again new, but familiar.

My view: Learn from the past; focus on the present; build for the future. Again, that is the root for design-operate-maintain (DOM)!