Today’s manufacturing operations and maintenance teams generate vast amounts of data in all forms. As a result, finding the right information, at the right time, and making it accessible to the right people are critical to keeping these functions operating at optimum levels. Companies trying to understand how to make better use of their data are turning to various types of analytics for answers. These include how to best manage the data, how to determine what data is truly valuable, and when and how to align technology and people to assist with making meaningful conclusions.

With digital transformation initiatives increasing the amount of data created and shared within today’s industrial organizations, making use of all this data can be a challenge. It’s not that this data isn’t relevant, but often some of the more meaningful and actionable nuggets are hid-den within a mountain of disparate data, both structured and unstructured.

It’s becoming increasingly difficult to make meaningful use of all the data being generated. This is particularly true for end users on the shop floor looking to expand their predictive maintenance and predictive analytics capabilities.

Data that was often managed separately in silos simply can’t be man-aged that way today. The implication is that maintenance and operations will need to have a much more cohesive vision around shared da-ta and analysis. This is why many industrial organizations seek analytics solutions that can be used by operations and maintenance personnel alike.

As industrial organizations adopt smart manufacturing methodologies, there is a growing need to acquire, access, and share equipment and sensor data, and then transform all this data into actionable information when and where it is needed.

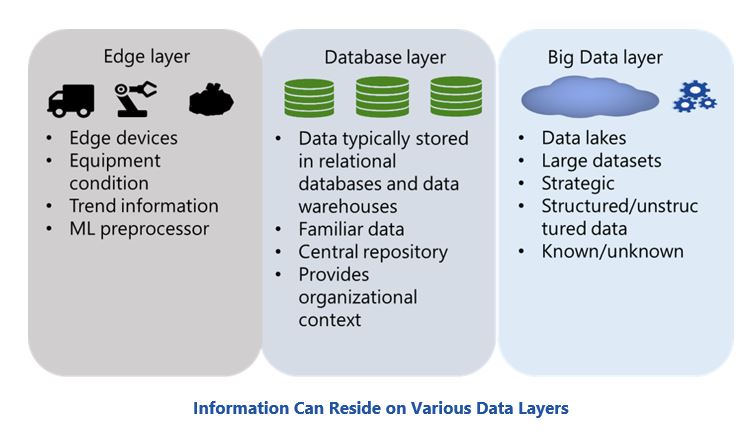

This data is typically generated near or at the edge layer (close to the point of origin), and processed, stored, and accessed at the database and Big Data layers. Moving forward, data will need to be managed closer to the origin point and then made accessible throughout the organization.

With all this data being streamed and stored in a wide variety of locations and systems, making practical use of it can be a challenge, since mining such disparate data can be difficult. Until recently, most soft-ware programs available required specialized expertise and investments in traditional and often costly analytics solutions. These solutions also have all the attendant services costs such as implementation and maintenance. In addition, the skill sets needed to use these solutions have traditionally been left to trained data scientists and statisticians assigned to organizations’ quantitative staffs.

For years, analytics solutions were deemed suitable only for large organizations with dedicated quant staffs. These teams commonly consisted of people with skills that ranged from report writing, business intelligence (BI), and SQL programming expertise, and experts skilled in various forms of predictive and quantitative analysis. Consequently, many industrial organizations have been reluctant to fund analytics projects at the operations and maintenance levels.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Analytics, Predictive Analytics, Enterprise Asset Management (EAM), Maintenance, Predictive Maintenance, Operations, Manufacturing, ARC Advisory Group.