In times of stress, like the current COVID-19 pandemic, some will jettison established procedures in an attempt to cut short term costs to manage quarterly profitability. Management may be thinking that, since we have less activity, we don’t need maintenance. But this approach is short sighted and positions the company for chaos and failure when recovery occurs.

Nearly all businesses have essential assets for producing the goods and services that provide revenue. Among firms currently experiencing a rapid decline in revenues with the COVID-19 pandemic, management feels extreme urgency – some would call it panic - to cut costs. Since activity is low, there is a temptation to eliminate maintenance.

Why maintain equipment operating well below capacity? The key metric for maintenance involves near-zero unplanned downtime for critical assets, which includes those used to produce revenue. Without maintenance, unplanned downtime increases causing chaos among the employees attempting to produce what revenue is available. With missed shipments, this chaos extends to customers at a critical time in their recovery. The resulting dissatisfaction translates into a sharp decline in brand value, revenues and shareholder value.

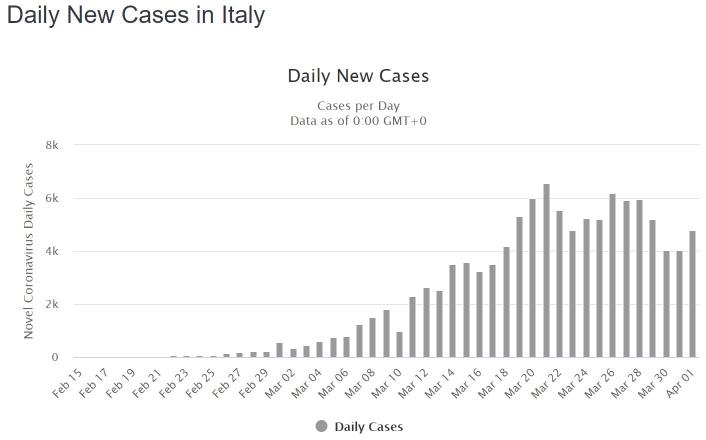

In terms of the progression of the disease, the US appears to be about two weeks behind Italy. The number of new cases peaked in Italy on March 21. For each day since, Italy has seen fewer new cases than that peak (Coronavirus in Italy). The number of daily new U.S. cases of COVID-19 should peak in two weeks. Statistics indicate that social distancing has slowed the spread in the US. Analysts estimate an 80 percent chance that the current patchwork of lockdowns, social distancing, and self-quarantine measures will prove effective, and daily new cases dropping down to very low levels by the end of May. That would allow the economy to re-start during in the third quarter.

Align this quarter’s needs with the next quarter. Though unemployment has increased, a large portion remained employed. Social distancing and self-quarantines created cabin fever and reduced spending – the combination provides significant pent-up demand. The time from establishing social distancing to business re-starting has been 2 to 3 months in countries where active cases of coronavirus has subsided. Next quarter, the expected lifting of social distancing should release a surge in spending. Those unemployed will quickly become employed adding to the spending surge. Expect demand sometime in the next two quarters to spike higher than prior to the pandemic. Those with well-maintained and reliable equipment will be positioned to respond to this new level of demand. Those companies that prepare for the recovery will profit.

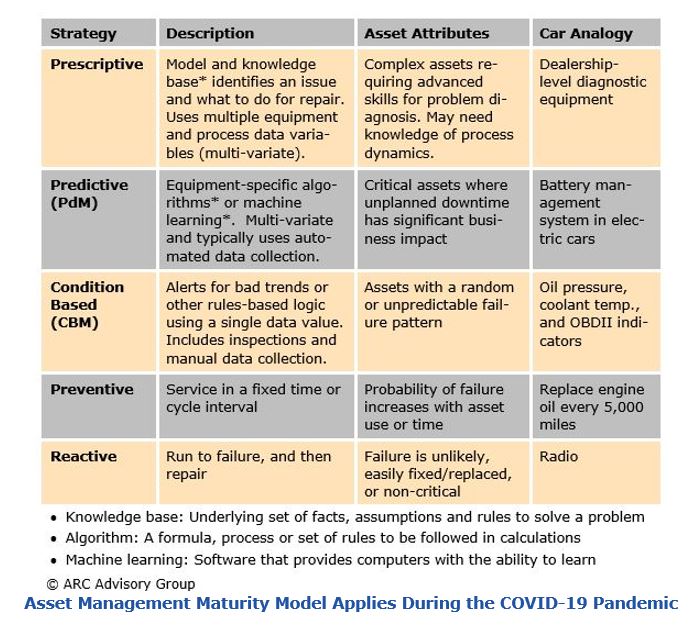

Consider going beyond just sustaining the existing maintenance strategy. This period of excess capacity provides an opportunity to upgrade the maintenance strategy for critical assets. Consider replacing preventive maintenance with predictive maintenance using “small data” from a specific machine for condition monitoring and generating an alert when things decay (reference IIoT Expands the Maintenance Maturity Model).

Research has shown that maintenance costs for a piece of equipment are reduced by half with Predictive maintenance (PdM) over preventive maintenance (PM). PdM schedules the work when it is really needed, i.e., as a problem starts emerging and prior to failure. Also since 82 percent of assets exhibit a random failure pattern (reference Improve Asset Uptime with Industrial IoT and Analytics), unplanned downtime occurs during the interval between scheduled PM. The equipment issues can be detected by PdM to avoid the random failures.

The most probable scenario has a surge in demand in the third and fourth quarters leaving unprepared companies in chaos. Don’t fall into that category. Keep your equipment well maintained.