I recently attended the Best Practices for Chemicals conference earlier this month in Austin, TX. Much of the messaging focused on the Digital Transformation and benefits. Ken Pierce, SAP’s Global Solutions Leader for IOT, started by presenting on how the IIoT changes the business for process manufacturing enterprises. He presented an overview of Leonardo as a portfolio of solutions that drive value and drive Innovation allowing users to focus on better outcomes and provide more value to customer. He then presented a list of companies in other process businesses and listed their results.

Mr. Pierce stated that Innovation consists of the right combination of People, Process, and Technology and that the Leonardo platform helps companies create the “Intelligent Digital Supply Chain of One.”

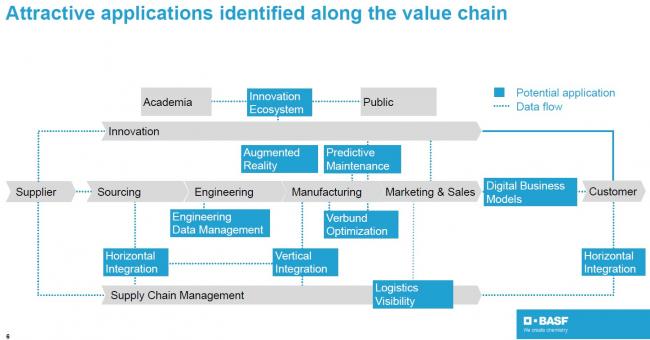

Andreas Klinger, Head of Digital Lab for BASF, followed with a presentation about BASF 4.0. He stated that BASF sees big potential in Cloud and Analytics. The company recently created an industrial fleet management pilot application using SAP’s Asset Integrity Network (AIN). BASF brought SAP, Endress & Hauser, and Samson together to create a solution that helps predict when sensors and valves require maintenance. Based on its observations, none of its suppliers could do achieve the results on own. Interestingly, none of the data passed through the control system, instead a second wireless communication was used from the devices to the Cloud. Was cybersecurity an issue? Absolutely. In this case all communication is one way and utilized a data diode. Mr. Klinger noted that the solution resulted in reduced maintenance cost through better planning of resources, as well as reduced or prevented abnormal situations.

My colleague, Valentijn de Leeuw, also reported some of this in a paper last year.

A panel discussion followed with both Mr. Pierce and Mr. Klinger. A few comments of note:

Dr. Thorsten Wenzel, SAP’s Vice President & Global Head for Chemicals, presented on what he sees in the industry in competing in the near term. He summed it up with four priorities: 1) Focus on outcomes not products; 2) Simplify to shrink cycle times; 3) Compete as an ecosystem 4) Increase your company’s market-driven strategic agility. Dr. Wenzel was joined by Patrick Thompson, CIO of Albemarle Corporation. Mr. Thompson reviewed his company’s journey to reinvent IT. Albemarle has a 3-tiered approach starting at the infrastructure layer, building into the business processes and completing with digital plant automation. Following Mr. Thompson, Jeff White CIO for Chemours discussed their ‘cloud journey.’ Some key takeaways include forgetting what you know, educate self and repeat quarterly, embrace the change, and keep focus on benefits.

More of the end users were looking to move to the new SAP platform, but many are looking for answers in dealing with the legacy customizations.

The SAP platform offers an interesting aggregation of seemingly disparate data across the enterprise. This ‘oneness’ promises to help end users by simplifying their IoT strategy.

Reiterating BASF’s observation, many IIoT solutions take multiple suppliers to create and implement.

Companies need to address the IT/OT divide.