The Asset Administration Shell (AAS), a key concept of Industry 4.0 (or “Industrie 4.0” in German), is used to describe an asset electronically in a standardized manner. Its purpose is to exchange asset-related data among industrial assets and between assets and production orchestration systems or engineering tools. This ARC Insight explains how the AAS is built, indicates some of the available documents on the subject, and provides a few application examples. As we’ll see, the first real application is the use of the AAS as an electronic label and description of an asset.

Industry 4.0 (I4.0) describes concepts for smart manufacturing to boost industrial output and competitiveness by improving efficiency, productivity, flexibility, and agility. Digitalization could also lead to new types of revenues by supporting the creation of new business models. A secondary purpose is to promote sustainability and safety, thereby allowing a sustainable coexistence between humans, industry, agriculture, and the natural world.

The I4.0 concept proposes tight and fast integration of production control, the product, and process lifecycle management with the value chains. This is also referred to as vertical and horizontal integration. Real-time sensing is required to generate the data needed to support optimization within the factory and across value chains. The concept uses analytics to exploit Big Data and end-to-end digital engineering to enable faster iterations between product/process design and manufacturing.

Industry 4.0 proposes to optimize production by using reconfigurable manufacturing lines in which production modules can be reorganized or reassembled quickly to match production needs. In a first stage, this requires plug-and-play automation of production modules. The next level of automation is the self-organizing and self-optimizing line or plant. Over the middle to long term, the concept targets the discrete manufacturing industry and fine chemicals, specialty polymers, and life sciences production. Longer term, the large-scale, commodity process industry may transition to small modular production units to reduce capital costs and may also be able to benefit from the I4.0 approach and associated technologies.

Rather than interpreting the state of a production facility by reading individual sensors and actuators, Industry 4.0 proposes to represent assets as an entity in the information realm to enable meaningful interaction with IT systems. I4.0 considers that assets are more than just machines, production modules, or systems; but also individual products, software installations, intellectual property, or human resources. An asset must be an identifiable entity, with a known asset type, asset lifecycle stage or instance, and asset state. Depending on the degree of the asset’s existing instrumentation, automation, and communication abilities, it may have to be retrofitted to enhance its abilities.

Industry 4.0 requires an asset to communicate in an I4.0-compliant manner by using a standard for communication. In addition to real-time parameters, the production capabilities and state of the asset must also be communicated. This logical representation of the asset is called the Asset Administration Shell (AAS). Together with the asset, the AAS forms the Industry 4.0 Component (I4.0 Component). The standardization of the administration shell reduces complexity and allows scalability.

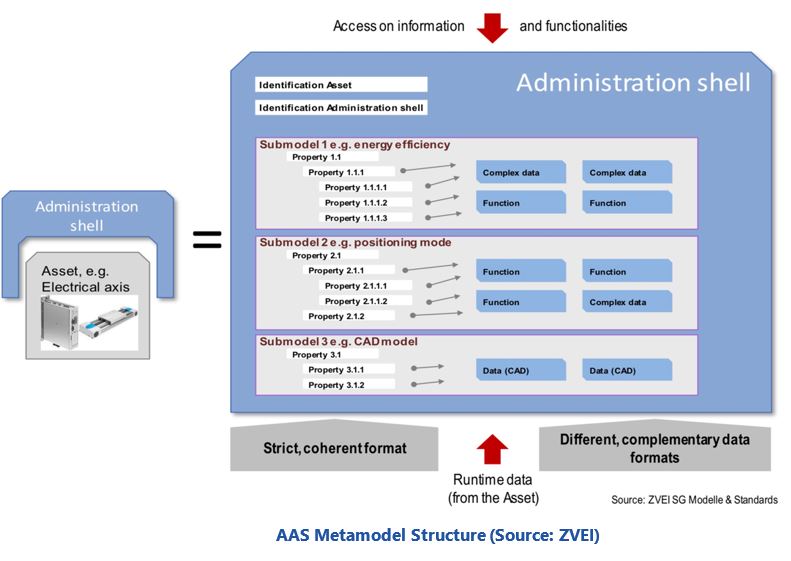

The AAS includes a concept of submodels, each of which can characterize the asset by describing its aspects in different domains. Domain examples include identification, communication, engineering, safety, security, lifecycle status, energy efficiency, health status, process control. Submodels also describe the asset’s functions: drilling, milling, welding, assembling, mixing, heating, reacting, etc. Each submodel is described by several properties defined by a unique global identifier and a set of well-defined attributes. AAS attributes are preferred name, symbol, unit of measure, definition, etc. Existing IEC and ISO standards are considered for use within the AAS for specifying properties and property values.

The Reference Architecture Model for Industrie 4.0 (RAMI 4.0) considers the asset lifecycle stage according to IEC 62890. In practice, we distinguish between asset designs and physical assets. The phase in which the asset is being designed is called type, representing the design of a type of asset. As soon as the asset is physically produced, it becomes an instance, an identifiable entity of a certain type. The relationship between the type and instance must be maintained along the life of the asset instances. In particular, updates of the type must be transmitted to the instance. An example could be the update of a product’s firmware.

A second aspect of the relationship could be the feedback from the product instance to the product type to support design and production improvements. Thirdly, exchange between assets of different asset classes can be used to design new types of products or manufacturing equipment. Finally, relationships between assets of different hierarchy levels determine a system of subsystems, for example the automation as subsystem of a machine.

The structure of the AAS must be standardized to enable exchanges. Examples and an advanced definition of this standard can be found in a downloadable document prepared by ZVEI, the German Electrical and Electronic Manufacturers' Association.

To exchange information, the AAS instance can be mapped to OPC UA, MQTT, or other formats. The AAS type is likely to be expressed in the

AutomationML standard.

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

Keywords: Asset Administration Shell (AAS), Industry 4.0 (I4.0), IIoT, RAMI 4.0, ARC Advisory Group.