It’s not enough anymore just to raise productivity. It’s not enough anymore just to be more flexible. It’s not enough anymore of just being faster to market. And it’s not enough any more just to achieve 100 percent quality. You have to do all of these things.

Words spoken there by Helmuth Ludwig, global head of information technology, Siemens, in his keynote address at Bentley Systems’ Year in Infrastructure 2017 Conference, which took place in Singapore for the very first time last month. The Siemens executive recalled the situation a decade ago when the company concluded that it needed to add new software capabilities to its well established automation portfolio in order to integrate the design process with the manufacturing process and enable its customers to move beyond making incremental improvements and take the next leap in competitiveness.

Since then Siemens has spent around $10 billion to acquire companies including UGS, Innotec, VR Context, Camstar, and Mentor Graphics, and with the increasing momentum of the digitalization trend, developed partnerships with the likes of Bentley Systems, IBM, Microsoft, and SAP. In late 2016, Siemens and Bentley evolved their technology partnership to a strategic alliance, involving the joint investment of €50 million to co-develop solutions based on converging their digital engineering models. Siemens also made a direct financial investment in Bentley Systems by purchasing €70 million worth of secondary shares.

Bentley Systems CEO Greg Bentley launches Year in Infrastructure Conference 2017 in Singapore.

Founded in 1984, Bentley Systems provides software solutions for the design, construction, and operations of infrastructure such as buildings, roads, rail, and power and water installations. Its annual Year in Infrastructure Conference features executive presentations, industry forums, technology demonstrations, and culminates in the Be Inspired awards ceremony, which recognizes innovation in infrastructure designed, constructed or operated with Bentley software.

This year in Singapore, with its strategic alliance in place, Siemens was visible through several stage appearances and its stand out on the exhibition floor, and both Bentley and Siemens were keen to articulate how their respective technologies can integrate to create new solutions and deliver value to both infrastructure and industry customers.

In a joint presentation, Siemens’ Torsten Beste, director strategic solutions, and Bentley’s John Sanins, senior director, solutions management, described how judicious integration of the two companies’ technologies enables connected asset visibility such that equipment problems detected in operation can be solved through rapid feedback to product development and by leveraging fully digital workflows to improve asset performance.

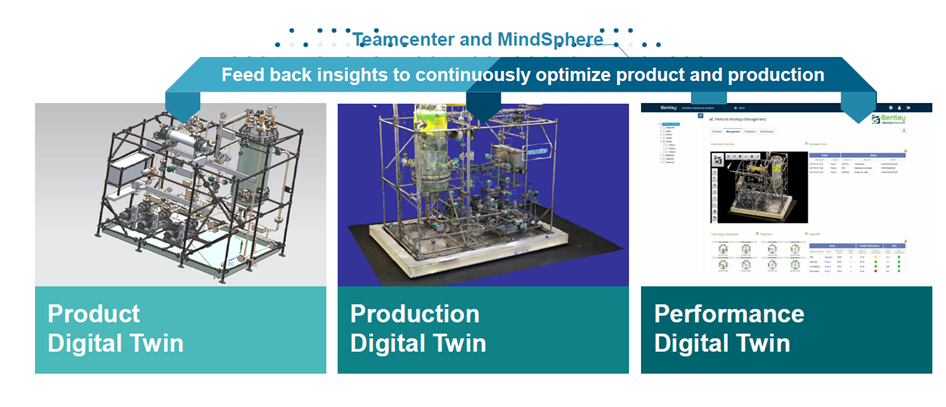

In a proof-of-concept of this at a demo plant in Karlsruhe, Germany, the first step involves making a digital representation of the process plant through the aid of photography and Bentley’s ContextCapture reality modeling software. The resulting 3D mesh is in effect a “production digital twin” of the physical plant. This links to the IoT-enabled components in the operating plant via MindSphere, Siemens’ cloud-based, IoT operating system. Bentley’s AssetWise Operational Analytics software is deployed in a MindSphere app such that in the context of the 3D model, a user can navigate this “performance digital twin” to query the health of various assets in the plant.

With the aid of AssetWise, an incorrectly operating pump is identified with the cause put down to a vibrating drive motor. The product design team now gets involved, using Siemens PLM software to access the “product digital twin” of the motor and design new motor mounts in order to solve the vibration problem. To ensure the redesigned motor will operate correctly (without vibration) in production, Simcenter software is used to simulate its behavior. Finally, the new motor mounts are 3D printed by an external vendor after an online RFQ process. It’s a great illustration of digitalization in action.

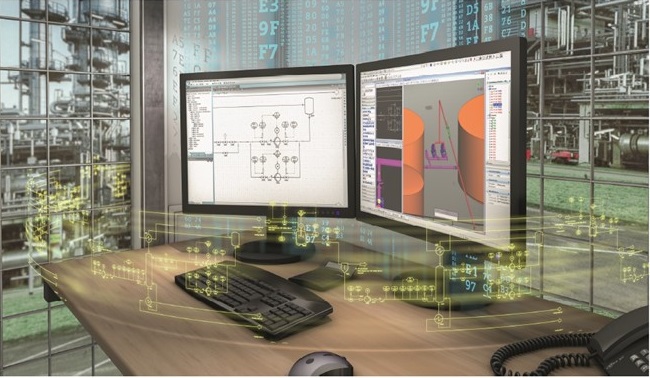

Another value-adding connection between Bentley and Siemens products involves COMOS and OpenPlant. COMOS is the plant engineering software tool that Siemens acquired through its 2009 purchase of Innotec. Among other features, it enables 2D design and generation of Piping & Instrumentation Diagrams (P&ID), and basic process engineering for the FEED phase of process plant design. OpenPlant is Bentley’s 3D plant design environment, which can model piping, HVAC, and electrical components. Integrating COMOS and OpenPlant allows for efficient data exchange between the 2D and 3D worlds. Plant designers can, for example, validate COMOS P&IDs against the 3D model in OpenPlant when making a design change.

lntegrating COMOS and OpenPlant enables efficient data exchange between the 2D and 3D worlds.

Aside from industrial plant, infrastructure areas targeted by the Siemens and Bentley alliance include power and transportation. With new distributed energy resources (DER) like wind, solar, and energy storage requiring electrical grids to be bidirectional, linking the GIS and network design capabilities in Bentley’s OpenUtilities with Siemens PSS SINCAL for network analysis modeling delivers an integrated DER planning and design assessment solution, which reduces data maintenance and IT integration costs and complexity.

Meanwhile, in the rail industry, the companies are working to industrialize the electrification process by integrating Siemens Sicat Master, for rail catenary overhead contact line modeling and analysis, with Bentley’s new OpenRail Designer, which provides detailed engineering and 3D design of track, overhead line, tunnels, bridges, and related civil infrastructure.

A point emphasized by both Helmuth Ludwig and Bentley Systems CEO Greg Bentley during the Year in Infrastructure Conference in Singapore: while manufacturing industry has seen major productivity improvements over the last 10 years, the same is not true for infrastructure, with the sector lagging both manufacturing and the general economy in terms of productivity growth, and project delays and cost overruns a frequent occurrence.

However, the increasing availability of digital solutions dedicated to infrastructure is an opportunity for this situation to finally change and the alliance between these two companies is a positive move to leverage their respective strengths and accelerate digital innovation in infrastructure. Indeed, additional joint projects are set to be announced over the coming year.