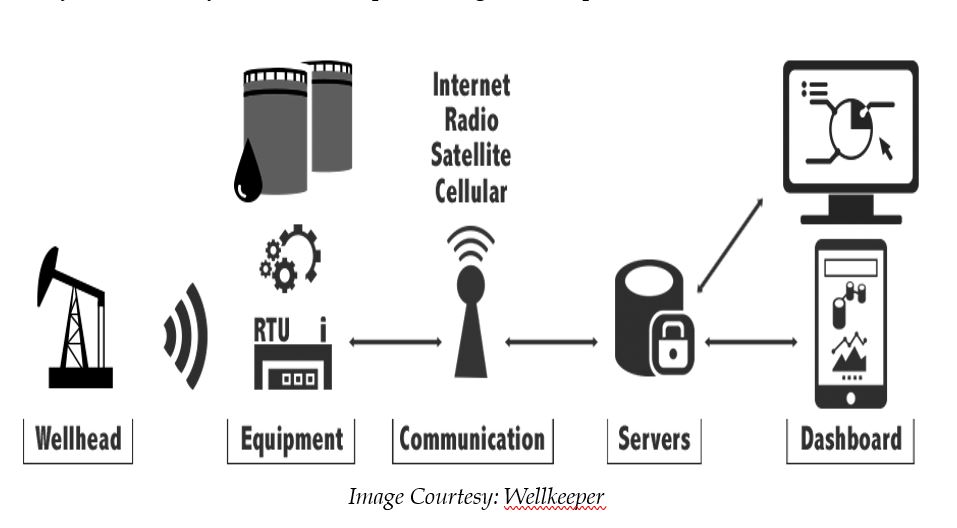

A comprehensive artificial lift optimization solution includes hardware components, such as vortex and Coriolis meters, remote terminal units, supervisory control and data acquisition systems, etc. But, the information technology backbone for optimization functionality is software that monitors, manages, and enhances the performance of wells and fields, and shows real-time production data at a glance on a single computer screen. Designed as a single-point tool to measure the operations of producing assets, the technology helps operators maximize performance by integrating real-time information from hardware and software networks to improve the overall productivity of their operations.

Advanced software packages not only provide reports, alarms, call-outs, data storage, and process data management on wells and fields, but they support higher-order management capabilities that look deep into the operation of each well to extract detailed production information that can be used to identify underperforming assets and optimize each asset in the network. Any process variable–flow rate, pressure, volume, etc. can be measured and analyzed to identify assets that are performing below expectations.

State-of-the-art human/machine interfacing (HMI) solutions are an important enabling feature. Once a production company has drilled a well, it needs to move quickly to complete it and get the production on line. Because the applications are data driven with fully automatic mapping, users can easily configure assets, wells, operator responsibilities, and other data, saving engineering and programming costs. Operators can quickly add hundreds of wells at a time to the configuration, and the solution contains proven templates to integrate real-time automation and information systems as well as SCADA hardware. This is particularly valuable for older fields that have multiple generations of automation equipment.

So, instead of requiring 60 man-hours to set up an individual well with the type of artificial lift, RTU and SCADA equipment, the user can configure a well in only an hour or two on a single configuration page. For companies with lots of wells or “manufacturing mode” plays, such as shales, the ability to quickly put the field management/optimization HMI on top of the automation capabilities for each new well or piece of equipment as it is added is critical.

In addition to optimizing production and reservoir performance, the information captured by these systems provides the framework to enhance business value. A company can assess such issues as energy consumption and maintenance expenditures to see where it is allocating limited capital and personnel resources versus where it should be allocating them to achieve the highest return.

The benefits of optimization resonate differently within different departments in an organization, but the “magic” is in exposing real-time information to professionals who never before have had access to it. As mentioned, giving reservoir engineers real-time production information gives them powerful new decision-making tools that can have a dramatic impact on drilling and development programs. On the other hand, managers focused on the bottom line will appreciate the business value of optimization. They now have the information to assess production performance and manage costs.

It is worth noting that focusing only on maximizing production will not necessarily make the most money. Neither will focusing only on cutting energy or maintenance/materials costs. Optimizing all these variables at the same time, however, can greatly enhance economics. It sounds simple, but it is very difficult to attain in a production operation, given all the dynamic variables.

ARC discusses the competitive technology and market scenario for IT and OT integration, connected devices, digitization and digital oilfield technologies in its recently published Artificial Lift Optimization systems market research report.

ARC welcomes the opportunity to speak with technology suppliers and users alike about your activities, thoughts, perspectives and questions on this exciting area. For further discussion or to provide feedback on this, please contact the author Jyoti Prakash at jprakash@arcweb.com.

Keywords: Artificial Lift, Optimization, IT & OT, IoT, Connected Devices, Digital Oilfield.