For decades, operating companies have used artificial lift optimization (ALO) systems to enhance oil and gas production. But in today’s “lower for longer” oil price market, which has been further exacerbated by COVID-19 pandemic adversely impacting demand, with owner-operators, independent E&P companies, and other industry stakeholders trying to squeeze out more profits per barrel of oil equivalent (or at least lower cost per boe), solutions designed to optimize artificial lift systems are in greater demand than ever. New age automation technologies, the trend toward digitalization, and the emerging Industrial IoT (IIoT), help further increase the value proposition for today’s artificial lift optimization solutions.

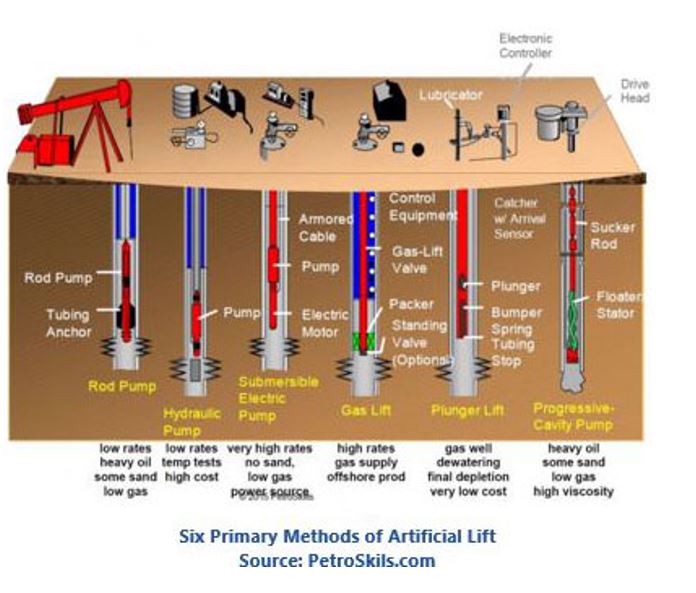

Most oil and gas wells operated throughout the world require some form of artificial lift during their lifecycles. Selecting the right lift technology requires detailed analysis; including gas, oil, and water property predictions; pressure loss from inflow to wellhead; variation in gas and oil ratio; and water cut over a period of time. Monitoring and optimizing the artificial lift system is equally important to selecting the optimal lift technology, because improper operation of the lift system generally leads to higher OpEx and subsequently CapEx investment. Monitoring is generally done using downhole and surface sensors that provide basic information about lift performance. However, this information is not always sufficient to determine if the well is running at the highest possible efficiency. Such calculations require a sophisticated mathematical model to capture the physical and chemical processes during the lifting process.

Although mature wells are more typical recipients of artificial lift systems, an increasing number of unconventional shale oil and shale gas wells now incorporate artificial lift at the outset of well production due to the steeper rates of decline than conventional wells. In addition, field production can be enhanced by employing different ALO solutions during different phases of a well’s production life. For example, deploying a jet pump or an electric submersible pump (ESP) system during the early and transitional phases of the well’s life, respectively, can be used in conjunction with rod pump systems deployed later in the well’s life to realize the largest estimated ultimate recovery (EUR).

ALO solutions are always being updated with new features to fulfill many changing market demands and increase their value proposition. We’re seeing growing demand for digital oilfields often based at least partially on Industrial IoT-based solutions and increasingly based on remote digital service capabilities. Digital oilfields provide opportunities to increase operational efficiency from the wellhead through the entire supply chain by optimizing data, information, and analytics ranging. Continuing innovations in sensor instrumentation, embedded advanced control algorithms, machine learning, and predictive condition monitoring on critical rotating equipment are all critical to the future of the smarter digital oilfield that will become integrated within the intelligent upstream value chain.

Some suppliers are struggling to identify the appropriate technologies and business structure to create an IIoT-enabled ALO ecosystem that improves their solution and/or service value proposition. Some owner-operators lack internal resources or domain expertise to leverage technologies, such as advanced analytics or machine learning, and could thus benefit from tapping into a larger ecosystem of third parties that can provide the missing expertise or resources. Like a play that’s still unfolding, any developments in Industrial IoT-enabled solutions still have more acts to play out, but that does not mean that suppliers should not begin to develop, or continue developing, potential roadmaps for product development and potential future business models. Owner operators, independent E&P firms and other stakeholders should increasingly seek out strong technology partners that possess both deep oil & gas domain expertise but also possess the resources and personnel to help customers fully exploit digital technologies in their journey towards digital transformation and operational excellence.

Recent ARC research into the market for Artificial Lift Optimization systems introduces several digital oilfield technologies and application for ALO systems and discusses the market based on system types and regions, etc. Specific system types covered in the research include electric submersible pump (ESP), hydraulic submersible pump (HSP), gas lift, jet pump, plunger lift, progressive cavity pump (PCP), and rod pump. The author welcomes the opportunity to learn more about your challenges and successes in deploying solutions or services designed to optimize your artificial lift systems. Please contact me at tshea@arcweb.com to share perspectives and more.